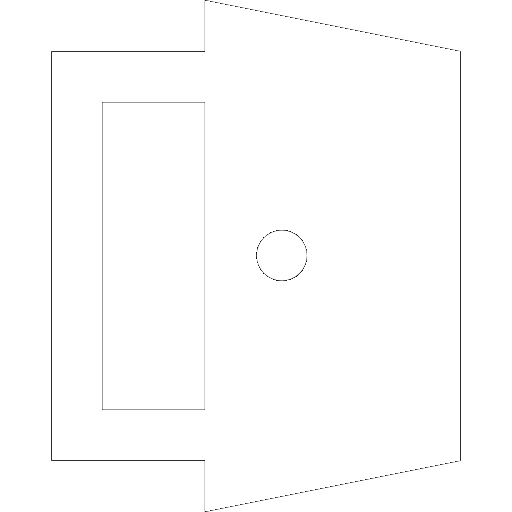

FOTOBA XLD 1700

The machine automatically cuts according to the marks in both the "x" and "y" axes. It handles both roll and sheet cutting, and the cutter can compensate for crooked sheet media foundation as well as the foundation of a running roll. The machine automatically compensates the cut to the edge of the printed image by reading the marks in both axes. It compensates for horizontal plane misalignment by rotating the cutting edge of the work table at the appropriate angle. In the vertical direction, the optical sensor holds the edge of the image. The smallest spacing between two vertical cuts is 28 cm.

The XLD 170 can handle most flexible media up to 0.8 mm thick, whether polycarbonate, photographic paper, vinyl, self-adhesive vinyl, PVC, film, canvas, or laminated or encapsulated prints.

To recognize the different types of crop marks by the optical system, they can be loaded into the memory of the cutter, so that when formatting prints from the same printer, only the memorized type of marks is selected and the start of the job is even faster. Stepper motors ensure accuracy with a tolerance of only 1 mm.