SRP has extensive experience in printing on textile materials and their finishing. As a result, we have been supplying textile prints to advertising agencies and end clients from the ranks of shopping parks or retailers and exhibition companies since 2006. Textile materials are becoming more and more popular in the large format printing market and are gradually replacing materials containing PVC.

They are easy to transport and the transport costs are lower due to their low weight. They are environmentally friendly.

From textile prints we supply:

- advertising flags for interiors - for exhibitions, shopping parks

- advertising and corporate flags for exteriors - flags for flagpoles, flags for bazaars

- textile banners for stands and rollups

- textile banners for facades

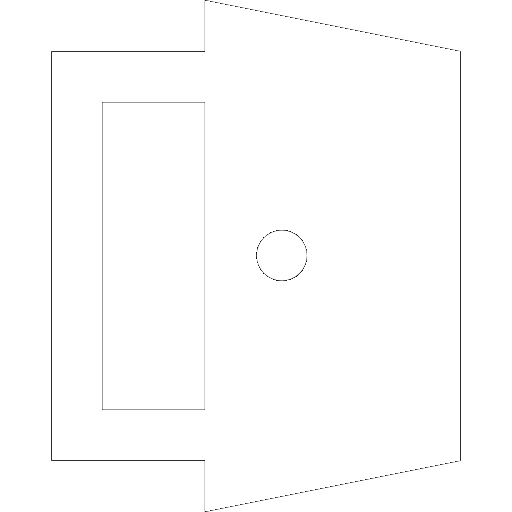

- textile banners for frame switching systems

- textile banners for illuminated switching systems (textile backlight)

- textile banners for hanging structures Retail - design and trade fair displays

- textiles for home decoration - tablecloths, curtains, cushions and upholstery

Depending on the environment for which the textile prints are intended, we always choose the appropriate materials, printing and sewing methods or other finishing processes.

For exteriors we use flagged and uncoated materials and sublimation printing.

Choice of technology for textile printing

The most important factors for the correct selection of the technology are the final use of the product and the desired properties. With digital technologies, it is always better to require a proof from the original data to check the colour. In fact, colour management of textile printing is much more demanding than with conventional technologies.

UV printing technology works on the principle of applying special inks and their immediate curing by UV light. The advantage is that the inks do not soak into the printed material and do not react with it in any way. Therefore, a really wide range of materials can be printed, including special materials. This technology offers photographic print quality and a wide colour range.

Sublimation printing is one of the transfer technologies and its essence lies in the use of two physical phenomena. A special ink applied to transfer paper can instantly change state from solid to gas, and by heating the material, the structure of certain polymers is loosened and their micropores are opened. It all works by transferring the selected motif from the special double-layer paper to the material during transfer in the thermopile, so that the pigment dispersed in the gas enters the material structure through the micropores and is fixed inside the material after cooling.

Sublimation technology is best used for printing on common textile materials, but can also be used, for example, to dye carpets. In conjunction with digital large format printing, it enables photorealistic print production for large-scale advertising and textile design purposes. In this way, printed textiles can be washed and normally maintained like other dyed ready-made textiles. We use Mimaki sublimation printers with print widths of 160 and 320cm

Solvent printing dominates in production speed and print width. Due to its high durability it is suitable for outdoor use. Printing with solvent inks, which are chemically bonded to the substrate media, is the most common method of large format printing today.

For interior applications we use both sublimation printing and UV printing on coated materials.

Delivery time for flag printing is within 3 days. We ship promotional flags within 24 hours!